Battery Cable Size Guide: A Comprehensive Overview (Updated 12/16/2025)

Volvo V40 owners frequently report “Low Battery Charge” warnings, even after battery replacement, often linked to the start-stop system and auxiliary battery interactions․

Understanding Battery Cable Importance

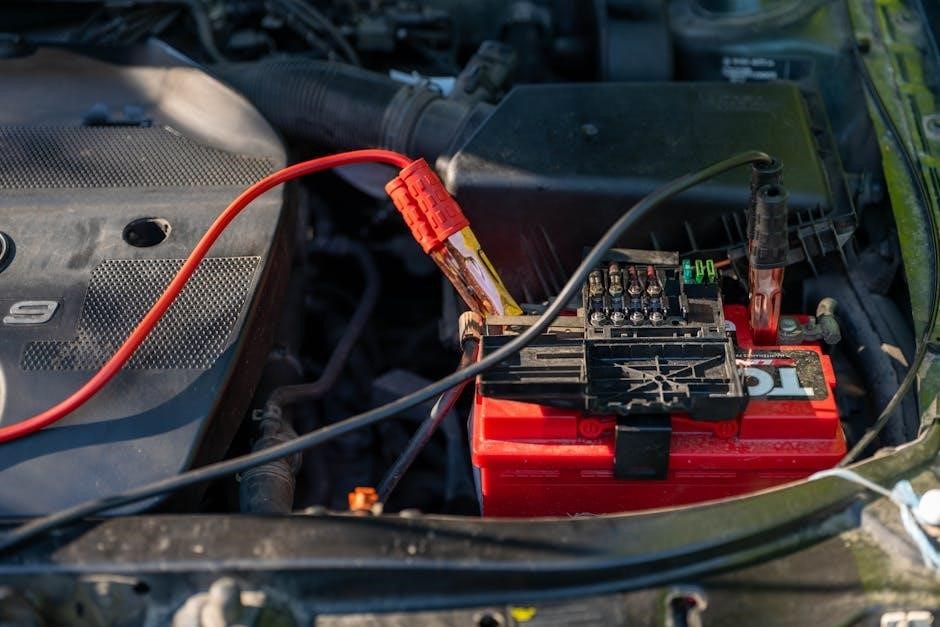

Battery cables are critical components within a vehicle’s electrical system, serving as the primary conduits for delivering power from the battery to the starter, engine control unit (ECU), and various other electrical accessories․ Their role extends beyond simply completing a circuit; they directly influence the reliability and performance of numerous vehicle functions․

Insufficiently sized or damaged battery cables can lead to a cascade of issues, including starting difficulties, reduced fuel efficiency, and even complete electrical failure․ Modern vehicles, particularly those equipped with start-stop systems and advanced driver-assistance systems (ADAS), place significantly higher demands on the battery and its cabling․

The Volvo V40, for example, demonstrates this complexity, with reports of persistent “Low Battery Charge” warnings despite battery replacements, highlighting the importance of cable integrity and proper sizing within these systems․ Ensuring adequate cable capacity is paramount for optimal vehicle operation and longevity․

The Role of Battery Cables in Vehicle Systems

Battery cables facilitate the transfer of substantial electrical current, initiating the engine’s starting process and continuously powering essential systems while the engine is running or even when it’s off․ They connect the battery to the starter motor, providing the high amperage needed for cranking․ Beyond starting, they supply power to the ECU, lighting, infotainment systems, and safety features․

In vehicles like the Volvo V40 with start-stop technology, the battery cables play a dual role․ They support regular starting demands and the frequent cycling associated with the start-stop function, alongside powering auxiliary systems during engine-off periods; The secondary battery, connected via a relay, briefly assists during restarts, placing further strain on the cabling․

Proper cable function ensures consistent voltage delivery, crucial for optimal component performance and preventing error messages like the frequently reported “Low Battery Charge” warning․

Consequences of Undersized Battery Cables

Utilizing battery cables with insufficient capacity can lead to a cascade of electrical issues, severely impacting vehicle performance and reliability․ A primary consequence is voltage drop – a reduction in voltage reaching vital components, particularly during high-demand situations like starting․ This can manifest as slow cranking, dim headlights, and erratic electronic behavior․

For vehicles equipped with start-stop systems, undersized cables exacerbate problems․ The frequent cycling stresses the cables, accelerating corrosion and increasing resistance․ This contributes to the “Low Battery Charge” warnings reported by Volvo V40 owners, even with fully charged batteries, as the system struggles to maintain adequate voltage․

Over time, undersized cables can overheat, damaging insulation and potentially causing short circuits or even fires․ Ultimately, they compromise the entire electrical system’s integrity․

Factors Influencing Battery Cable Size

Battery capacity, cable length, operating temperatures, and material composition all significantly impact the necessary cable gauge for optimal performance and reliability․

Battery Capacity (Amp-Hours)

The amp-hour (Ah) rating of a battery is a crucial determinant of the required battery cable size․ A higher Ah rating indicates a greater storage capacity and, consequently, the ability to deliver a larger current draw․ Therefore, batteries with higher Ah ratings necessitate thicker cables to handle the increased amperage without experiencing excessive voltage drop or overheating․

For standard starting batteries, typically found in older vehicles, the Ah rating might range from 40Ah to 70Ah․ However, modern vehicles, especially those equipped with start-stop systems or auxiliary batteries, often utilize batteries with significantly higher Ah ratings, sometimes exceeding 90Ah․

As the Ah rating increases, so does the potential for high current demands during starting or when powering accessories․ Selecting an undersized cable for a high-capacity battery can lead to reduced starting performance, diminished accessory function, and potential damage to both the battery and the vehicle’s electrical system․ Careful consideration of the battery’s Ah rating is paramount when choosing the appropriate cable size․

Cable Length and Voltage Drop

Voltage drop is a critical factor influencing battery cable size, directly correlated with cable length․ As electricity flows through a cable, some voltage is inevitably lost due to the cable’s resistance․ Longer cable runs exhibit greater resistance, leading to increased voltage drop․ Excessive voltage drop can severely impact the performance of electrical components, particularly the starter motor, and can even prevent the engine from starting․

The severity of voltage drop is also affected by the current draw․ Higher current demands, such as during engine cranking, exacerbate the issue․ Therefore, for longer cable runs, it’s essential to use thicker cables to minimize resistance and maintain adequate voltage at the connection points․

Calculating potential voltage drop based on cable length, current, and cable gauge is crucial․ Industry standards recommend keeping voltage drop below 3% for optimal system performance․ Ignoring cable length and voltage drop can result in unreliable starting and diminished electrical system functionality․

Operating Temperature and Cable Material

Both operating temperature and cable material significantly impact battery cable performance and sizing․ Temperature affects a cable’s resistance; higher temperatures generally increase resistance, exacerbating voltage drop․ Therefore, cables operating in hot engine compartments require careful consideration of temperature ratings․

Copper is the preferred material for battery cables due to its excellent conductivity and lower resistance compared to aluminum․ However, copper’s conductivity decreases with increasing temperature, necessitating larger gauge copper cables in high-temperature environments․ Aluminum cables, while lighter and cheaper, have significantly lower conductivity and are less suitable for demanding applications․

Cable insulation also plays a vital role․ High-quality insulation materials with appropriate temperature ratings are essential to prevent degradation and ensure long-term reliability․ Selecting cables designed for the specific operating temperature range is crucial for safe and efficient operation․

Determining the Correct Battery Cable Size

Accurately assessing ampacity, calculating potential voltage drop, and considering specific vehicle requirements—like Volvo V40 start-stop systems—are vital for optimal cable sizing․

Using Ampacity Charts

Ampacity charts are fundamental tools for selecting the appropriate battery cable size, detailing the maximum current a cable can safely carry․ These charts correlate wire gauge (cable thickness) with amperage, considering insulation type and operating temperature․ For automotive applications, where high currents are common during starting, a chart specifically designed for automotive wiring is crucial․

When consulting an ampacity chart, identify the expected maximum current draw of your vehicle’s starting system․ This information is often available in the vehicle’s service manual or through online resources․ Select a cable gauge that exceeds this current draw by a safety margin – typically 25% or more – to prevent overheating and potential damage․ Remember that longer cable runs necessitate larger gauges to mitigate voltage drop, a factor addressed in separate calculations․

For Volvo V40s with start-stop systems, the auxiliary battery and main battery circuits require careful consideration of ampacity due to the increased electrical demands․ Always prioritize a cable size that comfortably handles the peak current demands of these systems․

Calculating Voltage Drop

Voltage drop is a critical factor often overlooked when sizing battery cables; it represents the loss of voltage along the cable’s length due to resistance․ Excessive voltage drop can hinder starter performance, reduce accessory function, and contribute to the “Low Battery Charge” warnings seen in vehicles like the Volvo V40․ Calculating voltage drop involves considering cable length, current draw, and wire gauge․

A simple formula to estimate voltage drop is: Voltage Drop = (Current x Cable Length x Resistance per Unit Length)․ Resistance values are available in wire gauge tables․ Automotive systems typically aim for a maximum voltage drop of 3% during starting․ Longer cable runs, common in some vehicle designs, significantly increase voltage drop, necessitating larger cable gauges․

For Volvo V40 start-stop systems, accurate voltage drop calculations are vital, as the auxiliary battery circuit is particularly sensitive to voltage fluctuations․ Utilizing online voltage drop calculators can simplify this process and ensure optimal system performance․

Considering Vehicle Specific Requirements

Vehicle manufacturers often have unique electrical system demands that necessitate deviating from general battery cable sizing guidelines․ Modern vehicles, particularly those with start-stop technology like the Volvo V40, present complex requirements due to the interplay between the main and auxiliary batteries․

The Volvo V40’s intelligent alternator and regenerative braking system demand cables capable of handling fluctuating current loads․ Ignoring these specifics can lead to persistent “Low Battery Charge” warnings, even with fully charged batteries and correctly sized cables based on generic charts․ Consult the vehicle’s service manual for specific cable sizing recommendations․

Furthermore, the location of the battery and auxiliary components influences cable length, impacting voltage drop calculations․ Always prioritize the manufacturer’s specifications to ensure compatibility and optimal system functionality, avoiding potential issues with the start-stop system’s operation․

Battery Cable Size Recommendations by Application

For Volvo V40s with start-stop systems, prioritize heavier gauge cables for both main and auxiliary batteries to address regenerative charging demands․

Standard Starting Batteries

For vehicles equipped with standard starting batteries – those without advanced start-stop or regenerative braking systems – cable sizing is primarily dictated by the battery’s Cold Cranking Amps (CCA) rating and cable length․ Typically, a 2/0 AWG (American Wire Gauge) to 4 AWG copper cable is sufficient for most passenger cars and light-duty trucks with CCA ratings between 500 and 800 amps, assuming cable runs are under 10 feet;

However, longer cable runs or higher CCA batteries necessitate larger gauge cables to minimize voltage drop during cranking․ It’s crucial to remember that undersized cables can restrict current flow, leading to slow engine cranking, reduced starter performance, and potential damage to the starter motor․ Always consult ampacity charts and consider the vehicle manufacturer’s recommendations when selecting cable size for standard starting batteries, ensuring reliable starting performance in all conditions․

Deep Cycle Batteries

Deep cycle batteries, commonly found in vehicles with extensive auxiliary power demands or those used for off-grid applications, require significantly larger battery cables compared to standard starting batteries․ This is due to their ability to deliver sustained current over extended periods․ For deep cycle systems, a 2/0 AWG to 0 AWG copper cable is generally recommended for runs under 6 feet, especially with batteries exceeding 100 amp-hours․

Longer runs or higher capacity batteries may even necessitate 000 AWG or larger cables․ Voltage drop is a critical concern with deep cycle batteries, as it directly impacts the performance of connected accessories; Prioritize minimizing resistance to ensure consistent power delivery․ Always factor in the total current draw of all accessories when determining the appropriate cable size, and consult ampacity charts for precise recommendations․

Start-Stop Systems and Auxiliary Batteries

Vehicles equipped with start-stop systems and auxiliary batteries present a unique cabling challenge due to the complex power distribution network․ The main battery, often an Enhanced Flooded Battery (EFB) or Absorbed Glass Mat (AGM), requires robust cabling – typically 2/0 AWG to 4/0 AWG copper – to handle the high current demands of starting and frequent engine restarts․

The auxiliary battery, used to support start-stop functionality, generally needs 4 AWG to 2 AWG cabling, though this depends on its capacity and the length of the run․ Crucially, the connection between the main and auxiliary batteries, often via a relay, must be adequately sized to prevent voltage drop during start-stop events․ Volvo V40 owners have reported issues even after battery replacement, highlighting the importance of checking cable integrity and sizing․

Battery Cable Materials and Types

Copper cables are preferred for their superior conductivity, while stranded cores offer flexibility and resistance to vibration, crucial for automotive applications and longevity․

Copper vs․ Aluminum Cables

When selecting battery cables, the debate between copper and aluminum frequently arises․ Copper consistently outperforms aluminum in conductivity, meaning it offers less resistance to electrical flow for a given cable size․ This translates to improved starting performance, especially in colder climates, and reduced voltage drop across the cable length․ While aluminum is lighter and cheaper, its lower conductivity necessitates a larger cable gauge to achieve comparable performance to copper, potentially offsetting the weight savings․

Furthermore, copper exhibits superior corrosion resistance compared to aluminum, leading to a longer lifespan and more reliable connections․ Aluminum is prone to oxidation, forming a non-conductive layer that increases resistance over time․ Although specialized aluminum alloys and coatings can mitigate this issue, they add to the overall cost․ For critical applications like battery cables, where reliability and performance are paramount, copper remains the material of choice for most automotive professionals and enthusiasts․

Stranded vs․ Solid Core Cables

The construction of a battery cable – stranded versus solid core – significantly impacts its flexibility and durability․ Stranded cables, composed of numerous smaller wires bundled together, offer superior flexibility, making them easier to route within the vehicle’s engine compartment and minimizing the risk of damage from vibration or bending․ This flexibility is crucial in automotive applications where cables are subject to constant movement and varying temperatures․

Solid core cables, consisting of a single, thick wire, are less flexible and more prone to cracking or breaking under repeated stress․ While solid core cables might offer slightly lower resistance, the benefits of stranded cables in terms of reliability and longevity far outweigh this minor difference․ Automotive battery cables almost universally utilize stranded construction to withstand the harsh operating environment and ensure a consistent electrical connection over the vehicle’s lifespan․ Choosing stranded cables is a key factor in preventing intermittent starting issues․

Insulation Types and Temperature Ratings

Battery cable insulation is paramount for safety and longevity, protecting against short circuits, abrasion, and extreme temperatures․ Common insulation materials include PVC (Polyvinyl Chloride), which is cost-effective but has limited temperature resistance, and XLPE (Cross-Linked Polyethylene), offering superior heat resistance and durability․ Modern vehicles, particularly those with start-stop systems generating increased heat, often require XLPE or other high-performance insulation․

Temperature ratings are critical; cables must withstand the engine compartment’s heat and cold without becoming brittle or melting․ Look for cables rated for at least 105°C (221°F), and ideally higher for demanding applications․ Proper insulation prevents cable failure, reducing the risk of electrical fires and ensuring reliable vehicle operation․ Ignoring temperature ratings can lead to premature cable degradation and intermittent electrical problems, especially in Volvo V40 models experiencing battery charge issues․

Troubleshooting Battery Cable Issues

Common problems include corrosion, voltage drop, and intermittent connections—particularly in start-stop systems—leading to “Low Battery Charge” warnings and system malfunctions in vehicles․

Identifying Signs of Corroded Cables

Recognizing corrosion on battery cables is crucial for maintaining a reliable vehicle electrical system․ Visually inspect the cable terminals and connections for a white, blue, or green powdery substance – this indicates corrosion․

Furthermore, observe for any swelling or bulging of the cable insulation, as corrosion underneath can cause this․ A noticeable sulfur-like odor near the battery is another telltale sign․

Performance issues like slow engine cranking, dim headlights, or intermittent electrical failures can also point to corroded cables restricting current flow․

In Volvo V40s with start-stop systems, corrosion can exacerbate “Low Battery Charge” warnings and disable the start-stop functionality, as the system relies on a strong connection․ Regularly cleaning and protecting cable connections is essential preventative maintenance․

Diagnosing Voltage Drop Problems

Voltage drop testing is essential for identifying excessive resistance within the battery cable circuit, a common issue in vehicles experiencing electrical problems․ Use a multimeter to measure the voltage at both the battery terminals and the starter solenoid during cranking․

A significant difference – generally exceeding 0․5 volts – indicates excessive voltage drop, potentially due to undersized cables, corroded connections, or damaged wiring․

For Volvo V40s, particularly those with start-stop systems, voltage drop can trigger “Low Battery Charge” warnings and prevent the system from functioning correctly․

Testing should be performed under load, simulating normal operating conditions․ Addressing voltage drop issues ensures optimal power delivery and prevents further damage to the battery and electrical components․

Addressing Intermittent Connection Issues (Related to Start-Stop Systems)

Intermittent connections within the battery cable circuit can severely disrupt the operation of start-stop systems, leading to frustrating issues like the “Low Battery Charge” warning on Volvo V40s․ These systems are particularly sensitive to voltage fluctuations․

Carefully inspect both ends of the battery cables, as well as any intermediate connections, for corrosion, looseness, or damage․ Clean corroded terminals with a wire brush and ensure all connections are tight․

The auxiliary battery, used in conjunction with the main battery during start-stop cycles, is connected via a relay; check this relay’s functionality․

A failing relay or poor connection here can cause intermittent power delivery․ Thoroughly test and, if necessary, replace any suspect components to restore reliable operation․

Specific Vehicle Considerations (Volvo V40 Example)

The Volvo V40’s start-stop system demands careful attention to battery cable sizing and condition, as reported issues often involve the main and auxiliary batteries․

Main Battery Cable Sizing

For the Volvo V40’s main battery, proper cable sizing is crucial, especially given the vehicle’s start-stop functionality and the potential for “Low Battery Charge” warnings․ Owners have experienced issues even after replacing the battery with the correct EFB model, indicating cable-related problems might be present․ The original 70Ah battery was factory-installed in 2016, and subsequent replacements should maintain adequate cable gauge to handle the current draw during starting and regenerative charging․

Considering the system’s reliance on maintaining approximately 80% State of Charge (SOC) for optimal start-stop operation, the main battery cable must support consistent charging and discharge cycles․ Voltage drop is a key concern; a significant drop can trigger false warnings and disable the start-stop feature․ Diagnostic tools, like those from AUTEL, can help identify intermittent faults, but addressing the underlying cable capacity is essential․ Inspecting for corrosion and ensuring a secure connection are also vital steps․

Auxiliary Battery Cable Sizing (Start-Stop Systems)

The Volvo V40’s auxiliary battery, integral to the start-stop system, requires careful cable sizing, though its connection differs from the main battery․ This secondary battery isn’t continuously connected; it’s briefly engaged via a relay during engine restarts, providing supplemental power to alleviate the load on the main battery․ Despite this intermittent use, the auxiliary battery cable must be appropriately sized to handle the surge current during those critical moments․

Undersized cabling can hinder the auxiliary battery’s ability to effectively assist the main battery, potentially leading to start-stop system failures and persistent “Low Battery Charge” notifications․ While the auxiliary battery’s primary role is short-burst support, consistent performance relies on a reliable connection․ Ensuring proper cable gauge and secure terminals is paramount․ Remember, the system is designed to operate with a specific battery capacity and cable configuration; deviations can disrupt functionality․

Addressing “Low Battery Charge” Warnings

The persistent “Low Battery Charge” warning on Volvo V40s, even after battery replacements and charging, is a common issue often stemming from the intelligent battery management system․ This system monitors battery state of charge (SOC) and can trigger the warning even if the battery appears functional․ The system aims to keep the main battery around 80% SOC to maximize regenerative charging capacity for the start-stop function․

Diagnostic tools, like those from AUTEL, can reveal if the fault code has temporarily cleared, but the underlying issue might remain․ Checking sensor readings is crucial․ Furthermore, ensure both batteries (main and auxiliary, if equipped) are the correct specified models․ A 100-mile drive and overnight smart charging can sometimes resolve the issue, but if the warning persists, investigate cable connections and potential voltage drops․ Consider the interplay between the main and auxiliary batteries within the start-stop system․